| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Lebron-Machinery

Model Number : YX68-610

Certification : ISO, CE certificate

Place of Origin : Wuxi City, Jiangsu

MOQ : 1 Set

Price : USD 30000~50000 per Set (Negotiation)

Payment Terms : L/C, T/T

Supply Ability : 30 Sets per Month

Delivery Time : 25-30 days

Packaging Details : Export Sea-worthy packing with steel wires tie and fixed in the container

Main Power : 15KW

Roller Stations : 20 Stations

Roller Material : 45# steel

Suitable Material : Galvanized Steel Coil

Shaft Diameter : 90mm

Forming Speed : 12~15m/min

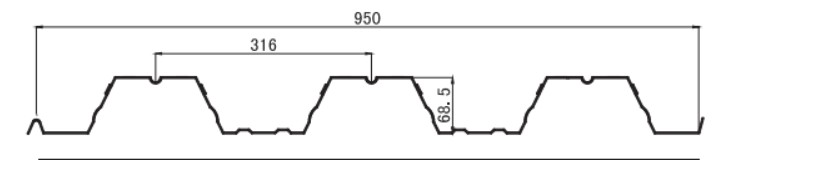

YX 68.5 316 950 Type Automatic Floor Deck Roll Forming Machine Forming Speed 12 to 15m per min

1. Description of floor deck roll forming machine

The floor calendering machine is manually used to produce steel floors. It can produce high-quality floors with no cutting deformation, high strength, and heavy workload. It can be directly mixed with steel mesh and concrete and has good adhesion. It is suitable for high-rise steel structure buildings. It can save steel formwork and reduce floor load. Under the same capacity, the amount of steel can be reduced, thereby saving costs.

There are different steel floor deck roll forming machines manufacturing metal decks for different applications, and the configuration or components of each machine vary accordingly, for example, some deck machines have embossing rolling tools while some others do not.

The deck forming machine consists of an uncoiler and its base, coil guide equipment, roll forming system, post-cutting equipment, hydraulic station, PLC control system, and support table. The corrugated profile produced by this machine has high strength and large ribs, which can be well bonded to concrete. It is best used as the floor of high-rise buildings, and the construction cost of the floor is low.

As a Chinese enterprise, Lebron-Machinery has been awarded that metal deck roll forming machines have been increasingly popular in the Chinese market, and in China over 90% of steel deck roll forming machines buyers produces metal floor deck and that’s why in China a deck roll forming machine is most of the time named as metal floor deck roll forming machine or steel decking floor roll forming machine.

2. Main technical parameters of floor deck roll forming machine

| No. | Item | Description |

| 1 | Suitable Material | Hot-dipped galvanized steel coils |

| 2 | Thickness of Material | 0.8mm-1.5mm |

| 3 | Roller Stations | 20 stations |

| 4 | Diameter of Shaft | 90mm |

| 5 | Material of Shaft | 45# steel |

| 6 | Material of roller | 45#steel with quenching treatment and coated with hard chrome 0.05mm thickness |

| 7 | Forming speed | 12~15m/min |

| 8 | Main Power | 15KW |

| 9 | Overall Dimension | 13.5mx1.5mx1.3m |

| 10 | Weight of the machine | Approx. 12 Tons |

| 11 | Cutting | hydraulic cutting |

| 12 | Material of Cutting Blades | Cr12 steel |

| 13 | Hydraulic Power | 4KW |

| 14 | Control system | Panasonic PLC, Inverter, CHNT transformer, and Omron encoder |

|

|

HDG Metal Floor Deck Roll Forming Machine 12 - 15m/Min Speed Images |